YLFDJ Soundproof Canopy Introduction

STANDARD TYPE

● The arc angle structure makes the appearance beautiful and not easy to bump

● High quality coating powder, chemical surface treatment & 100-120um coating thickness greatly improving the anti- corrosion and anti rust level

● Stainless steel hinge & door lock are beautiful and anti-rust

● 2.0mm cold rolled plate used makes the body more solid

● The bottom forklift and loading port design enables easy loading and unloading

● The drainage outlets are all connected to the outside for easy operation

● The sufficient air in & out design ensure long-term and stable operation of the unit

● Isolation net is designed for air inlet, exhaust outlet and muffler outlet to prevent objects from entering the unit

● High density foam used inside effectively reduces noise

● Ceiling Lighting is equipped for easy operation

● The built-in base fuel tank with fuel filler set on the shell facilitates refueling

● Models above medium power range are designed with top hoisting mechanism to facilitate transportation of the unit.

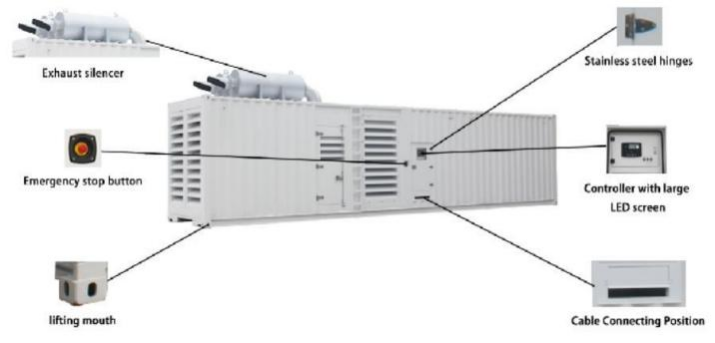

CONTAINER-IN TYPE

● The shell is made of 3.0mm hot rolled steel plate so as to withstand the lifting capacity of 15-ton without deformation

● The switch cabinet and control panel are respectively set on both sides of the shell for easy maintenance & operation

● The shell looks similar to standard container, and can be loaded into 40HQ container for transportation, which is convenient for shipping

● The lifting eye holes are designed on the top same as the standard container for easy handling

● High density foam used inside effectively reduces noise

● The built-in base fuel tank with fuel filler set on the shell facilitates refueling

● Double emergency stop button set on different surfaces enables quick response to operation requirements

● The shell base is independent from the unit with 3mm thick checkered steel plate floor, which is beautiful & antiskid, and is convenient for overhaul & maintenance of the unit

● The door handle, lock and hinge are all made of stainless steel to avoid rusting

● The air out louver made of the mesh plate with podwer coating and pasted with high-density glass fiber is beautiful and not easy to rust, and can further reduce the noise

● Isolation net is designed for air inlet, exhaust outlet and muffler outlet to prevent objects from entering the unit

● The sufficient air in & out design ensure long-term and stable operation of the unit

● The drainage outlets are all connected to the outside for easy operation

● Ceiling Lighting is equipped for easy operation

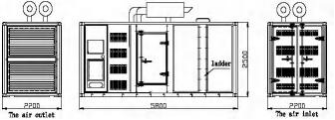

STANDARD CONTAINER TYPE

● Can be shipped on board directly during transportation

● The mesh plate with podwer coating and inner pasted with high-density glass fiber is installed inside the shell, which is beautiful and anti-rust, and can further reduce the noise

● 3mm thick checkered steel plate floor is beautiful & antiskid, and is convenient for overhaul & maintenance of the unit

● Double emergency stop button set on different surfaces enables quick response to operation requirements

● The independent daily fuel tank can be designed to put inside to meet requirements of continuous operation

● The fuel filler is set on the shell to facilitate refueling

● The switch cabinet and control panel are respectively set on both sides of the shell for easy maintenance & operation

● The air in & out louver made of the mesh plate with podwer coating and pasted with high-density glass fiber is beautiful and not easy to rust, and can further reduce the noise

● Isolation net is designed for air inlet, exhaust outlet and muffler outlet to prevent objects from entering the unit

●The sufficient air in & out design ensure long-term and stable operation of the unit

● The drainage outlets are all connected to the outside for easy operation

● Ceiling Lighting is equipped for easy operation

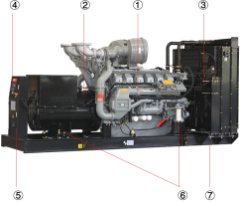

Decomposition diagram introduction of YLFDJ Typical Canopy

STANDARD SUPPLY SCOPE

⑧

⑨

⑩

① Engine

② AC Alternator

③ Cooling Radiator

④ Auto Start Control Panel

⑤ Main Ciruit Breaker

⑥ Built in Shock Pad

⑦ High Strength Frame

⑧ Exhaust silencer

⑨ Bellow

⑩ Starting battery

OPTIONAL SUPPLY SCOPE

Genset | Engine | Alternator | Control system |

● Toolbox ● Base fuel tank ● External daily fuel tank ● Trailer | ● Fuel heater ● Fuel and water separator | ● Temp. detector for winding and bearing ● PMG ● Anti rust, mildew and salt fog treatment ● Anti condensation heater | ● ATS ● Synchronization System ● Adjustable earth relay |

Breaker | Fuel system | Lub-oil system | Cooling system |

● ABB ● Schneider | ● Low fuel level alarm ● Auto Fuel Pump ● T Vlave | ● Lub oil heater ● Temp.-sensor ● Oil drain Pump | ● Elec.coolant Heater |

General Data

GENERAL DATA | |||

Model | YLGF-728CCS | ||

Prime Power | KW/KVA | 728 | 910 |

Standby Power | KW/KVA | 800 | 1000 |

Frequency/Speed | Hz /RPM | 50 | 1500 |

Rated Power Factor | / | 0.8 | |

Standard Voltage | V | 220 | 400 |

Current | A | 1310 | |

Connection | / | 3P 4W/Y | |

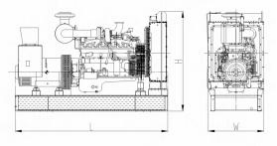

Open Type <LW*H) | mm | 4400*1850*2380 | |

Open Type(Weight) | KG | 7200 | |

Silent Type (L'WxH) | mm | 5800*2280*2500 | |

Silent Type(W'elght) | KG | 8800 | |

Base fuel tank | L | 1000L | |

Open Type

Silent Type

1. Available for voltages 400/230v,480/277V,380/220V,440/254V,416/240V,220/127V,208/120V

2. Al datas based on ISO 3046, altitude 100m (328ft), barometric pressure 100kPa (29.53inHg), alr temperature 25 ℃(77°F), relative humidity 30%

3. The present diesel generators comply with standards:ISO 9001 , ISO 14001, ISO 45001 , CE by UDEM

STNDARD CONFIGURATION | |

Engine | Cummins, including air filters, fuel filters, oil filter, starting motor and charging alternator etc. |

Alternator | Leroy somer TAL-A49-D |

Radiator | Silent Type 50℃(Open Type 40℃), fan protective shroud |

Base Frame | ≤550KW: base mounted fuel tank, anti-vibration pads, battery holder >550KW: channel steel base frame, anti-vibration pads, battery holder |

Circuit Breaker | >1250A : Air circuit breaker(ACB) |

Control System |

COMAP IL3AMF25BLA |

Start Battery |

Dry charged battery, available for 6 times starts under standard condition; connection cables |

Installation Accessories |

Bellow, Elbow and flange, Exhaust silencer, etc. |

TooI | Power Stream standard |

Documents | Electric drawing, operation & maintenance manual, certification etc. |

OPTIONAL CONFIGURATION

Engine Accessories | Heavy-duty air filter , Coolant heater , Lub oil heater , Fuel and Water Separator |

Alternator And Accessories | Marathon, Anti-condensation heater , High voltage kw |

Cooling System | Remote horizontal water tank syste, 50'Cradiator , Heat exchanger + water cooling tower + External water circulation pumping system, |

Control system | AMF , Parallel , Practical type in low temperature environment , Control Screen Heater , Other(Comap、DEIF , SmartGen ) |

Circuit Breaker | 3/4 poles , Fixed/handcart type , Electric mechanism |

Automatic Transfer Swtich | ATS cabinet |

Start Battery | Nickel-cadmium battery , Maintenance-free battery , Power charger and selector , Charging current meter |

External Fuel Tank | 500L 1000L 1500L 2000L 2500L 3000L 4000L 5000L 10000L |

ENGINE DATA | ||

Engine Model | KTA38-G2A | |

Aspiration | Turbocharged Aftercooled | |

Type | 60° Vee | |

No. ofCylinders | 12 | |

Governor Type | Electronic Governor | |

Engine Power | KW | 896 |

Displacement | L | 38 |

Bore * Stroke | mm | 159*159 |

Compression Ratio | 14.5:1 | |

Rated Speed | rpm | 1500 |

FUEL SYSTEM | ||||

Prime Power Fuel Consumption | L/h | 194 | ||

Standby Power FuelConsumption | L/h | 215 | ||

Fuel # | ASTM D975 No.2-D orBS2869 1998 Class A1, A2 | |||

Injection System | PT | |||

LUBRICATION SYSTEM | ||

Lub Oil Capacity | L | 135.1 |

Max.Temperature | ℃ | 121 |

Lub # | API CF-4 15W40 | |

COOLANT SYSTE | ||

Coolant Capacity |

L |

240.8 |

Std. Thermostat (Modulating) Range |

℃ |

82-93 |

Max. Top Tank Temp | ℃ |

104 |

Fan Drive Method | Shaft drive | |

Cooling Fan Air Flow |

m3/min |

1400 |

AIR INTAKE SYSTEM | ||||

Combustion Air Flow | m3/min | 60.06/ 64.02 | ||

Maximum Air Intake Restriction |

kPa |

3.7 | ||

EXHAUST SYSTEM | ||||

Exhaust Gas Flow |

m3/min | 165.54/ 179.7 | ||

Max.Back Pressure |

kPa |

13 | ||

Exhaust Gas Temp |

℃ |

≤521 | ||

Exhaust Pipe Size |

mm |

? 150x2 | ||

STARTING SYSTEM | ||||

Start Mode | DC24V Electric start | Battery | 4x200 | |

Alternator and Control system Data

ALTERNATOR DATA | ||

Alternator | Leroy somer | |

Alternator Model | TAL-A49-D | |

Rate Power | KW/KVA | 728/910 |

Voltage | V | 230/400 |

Phase | 3 | |

Frequency | Hz | 50 |

Connection | 3P 4W/Y | |

Winding Pitch | 2/3 | |

Insulation Class | H | |

Tel. influence | TIF:<50 | |

Harmonic Coefficient | THF:<2% | |

Voltage Adjust scope | ≥±5% | |

Bearing | 1 | |

Proteccion Class | IP21 | |

Efficiency | 95% | |

Voltage Regulation | ±1.0% | |

AVR | P150 | |

Excitation System | SHUNT | |

CONTROL SYSTEM DATA

ComAp IL3AMF25BLA

1. Single-unit generator set controller for common or standby unit applications.

2. Easy to install, configure and use

3. The controller has 5 built-in languages

4. Level 3 cipher

5. 3 alternative configurations

6. Direct communication with EFI engine

7. Applicable to T4 Final

8. Comprehensive remote monitoring and control

9. Cloud-based monitoring with WebSupervisor

10. Supports a variety of communications:

11. Connect via RS232, RS485, CAN and onboard USB

12. Internet access is available using Ethernet, GPRS, 3G or 4G

13. Support Modbus (TCP/RTU) and SNMP (v1 / v2c - including traps)

14. Send unsolicited text messages and emails

15. Track WebSupervisor with Geofencing

16. Built-in PLC and PLC monitoring tool included in Inteliconfig

17. Onboard 12 inputs and 8 outputs

18. 2x 10 A binary output for starting and fuel solenoid valves

19. More I/O is available through plug-ins or CANmodules (CM-BIO8-EFCP, Inteli AIN8, Inteli IO8/8, IGS-PTM).

20. Remote alarm on CAN

21. Activate output based on input

22. Load shedding, virtual load capacity

23. Real-time clock (with battery)

24. Versatile flexible timer

25. History log with up to 350 messages

26. True RMS measurement

27. Comprehensive protection

28. The protection function can be disabled

29. Available in low temperature version (ordering code: IL3AMF25BLA)

30. UL certificate