INTRODUCTION

The front REACH STACKER is mainly used for the loading and unloading, transportation and stacking operations of various specifications and other materials in ports, docks, stacked yards and other places.

FEATURES

①Advanced Technology Excellent Truck Quality

l With multiple advantages, the truck has high safety / high efficiency / high precision and high stability performances. Integrated operating system ensure the truck highly productive.

②Full Can-bus Control System

l Equipped DM450 reach stacker is equipped with full Can-bus control system. The engine / transmission / electric system / hydraulic system / loading safety system / spreader system are all integrated in the Can-bus system, all devices are monitored at real time. Parker control units ensure the system reliable and flexible.

③Hydraulic system of DM450 Reach Stacker

l World class Linde hydraulic company is the famous hydraulic solution supplier which supply the high-quality / high precision / high reliability hydraulic products.

l DM450 is equipped with Linde pump and control valve, these parts are specially developed for reach stacker, with load sense control circuit saving energy, precise control, low resistance and long life time, this excellent hydraulic system fully support truck excellent performance.

l Intelligent hydraulic oil cooler can ensure the stable oil temperature and avoid the tremendous changing of the oil, prolong the oil lifetime to save money.

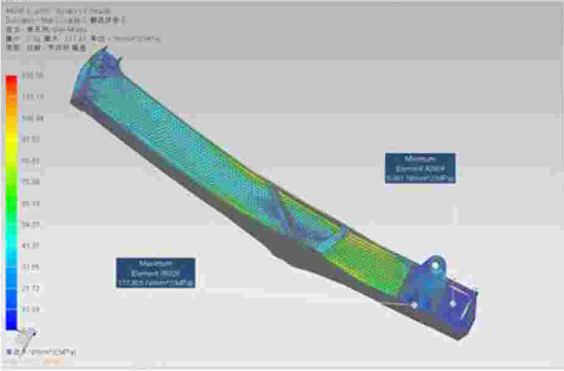

④Rigorous design process

l FEM analysis supported design provides high strength of chassis and boom, make whole truck stable and robust.

⑤ Core technology

l Dynamic anti-tip over protection

l Load sense hydraulic system

l Vertical lifting function

l Errors automatic detection and real data showing technology

l Anti-collision protection for spreader and boom

l Full Can-bus communication

l Movable cabin

l Separate brake tank

l Pressurized hydraulic tank

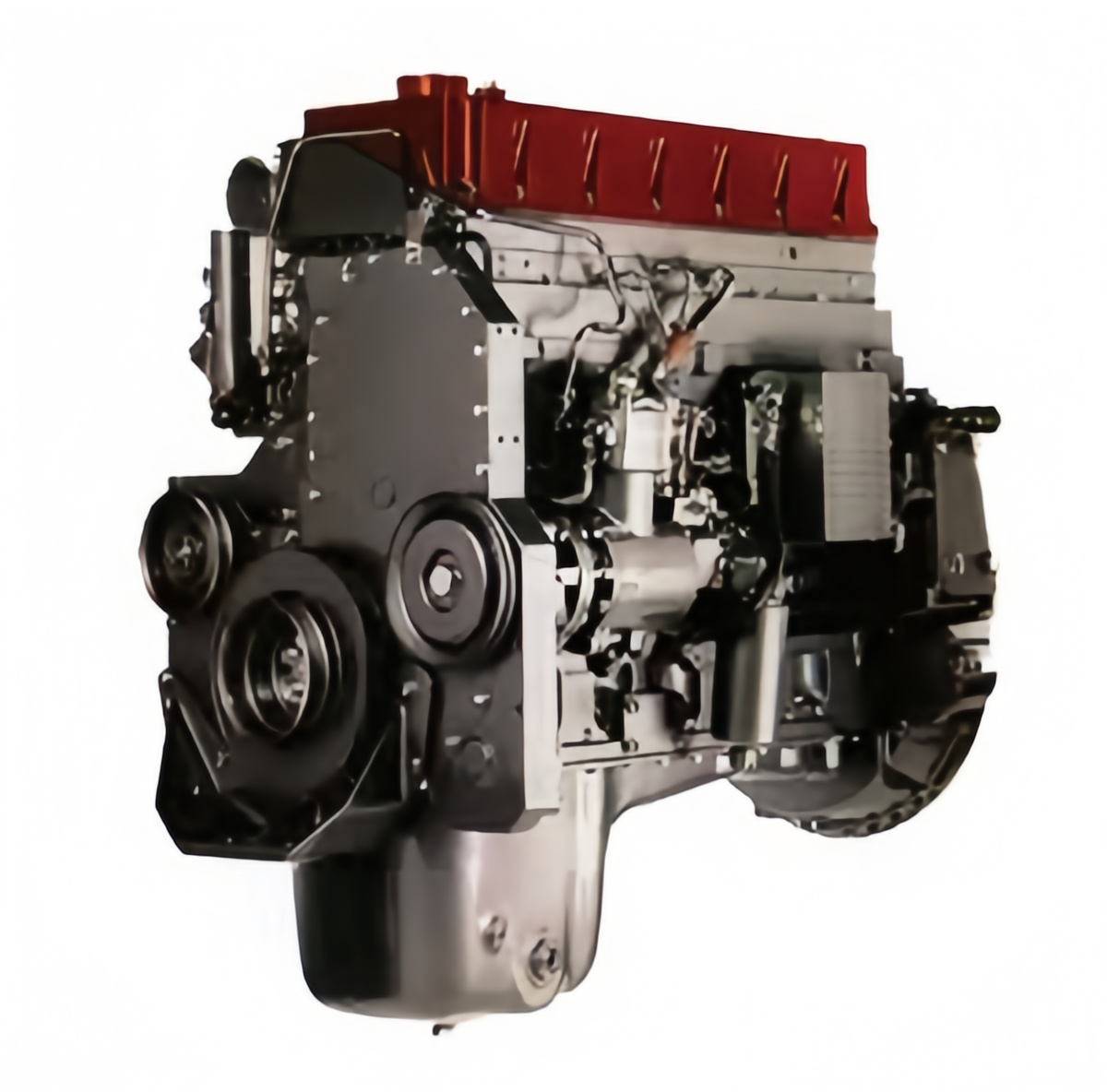

⑥High Quality Powerful Engine

l Equipped with Cummins engine, with full electrical control system to ensure economic fuel consumption

l Equipped with turbocharger to improve the truck power and engine efficiency

l Strong power to meet various working condition

l Comply with EU stage Ⅲ gas emission standard

l Full lubrication performance to ensure the low noise level

l The electric engine protection system shutdown the engine to avoid the damage when low lub-oil pressure / high temperature

⑦The Automatic Transmission

l DANA automatic transmission

l Auto-gear transmission with 4 forwards / 4 reverse speed, makes the truck operation smooth and good economic performance

l Minimum maintenance, long life time

l Inching function ensure the accurate approaching performance

l Reversing interlock, speed controlled downshift protection

⑧Heavy Duty Drive Axle

l Drive axle, proven quality for heavy duty truck, wide track, 2-stages reduction gear box,strong axle body optimized for heavy loading condition, wet disk driving brake is free of maintenance. This drive axle performs under shock load condition ensuring high safety and long life time.

⑨Control system Special features

l Display code and content, not need to view manual book. Save time.

l The DM450 reach stacker is currently using the advanced integrated fuse box unit, and the control box is beautiful and small. All the fuses are concentrated.

⑩Touch-sensitive / High resolution Color Display

l A reliable color display shows the lifting weight / boom angle / lifting height / main pressure / engine status / oil level / error codes etc. All important information. The quick responding controller helps the operation high efficiency.

⑾Spacious Driving Environment

l The cabin adopts the latest ergonomic design, Simple & elegant, Spacious & comfortable.

l Equipped with large-color display for easy reading the real status of the truck.

l Film cabin design to ensure the safety and comfort of the operator. Good tightness, the doors & windows can be opened & closed easily and firmly.

l Equipped with multi-function joystick. All the control are at your fingertips.

l The luxury seat can be adjusted according to the driver's height and weight to ensure the most comfortable driving and high efficiency. The safety glass to ensure the excellent all-round visibility.

l Equipped with Air-Conditioner with heating function to suit working in all climates.

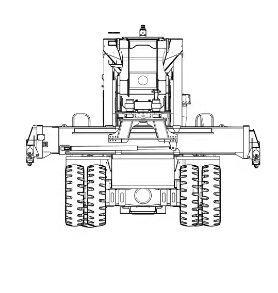

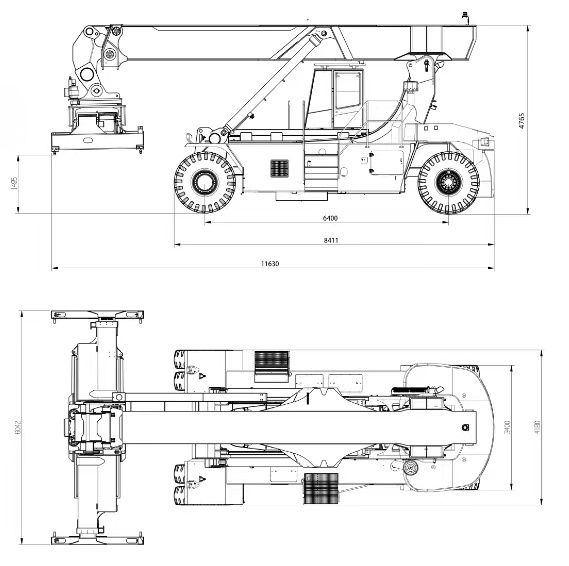

OVERALL

SPECIFICATIONS

| Characteristics | Model designation | DM450/5 | |||||||

| Power unit: battery, diesel, LP gas ,mains power | Diesel | ||||||||

| Operation: manual, pedestrian, stand-on, order picker | Rider seated | ||||||||

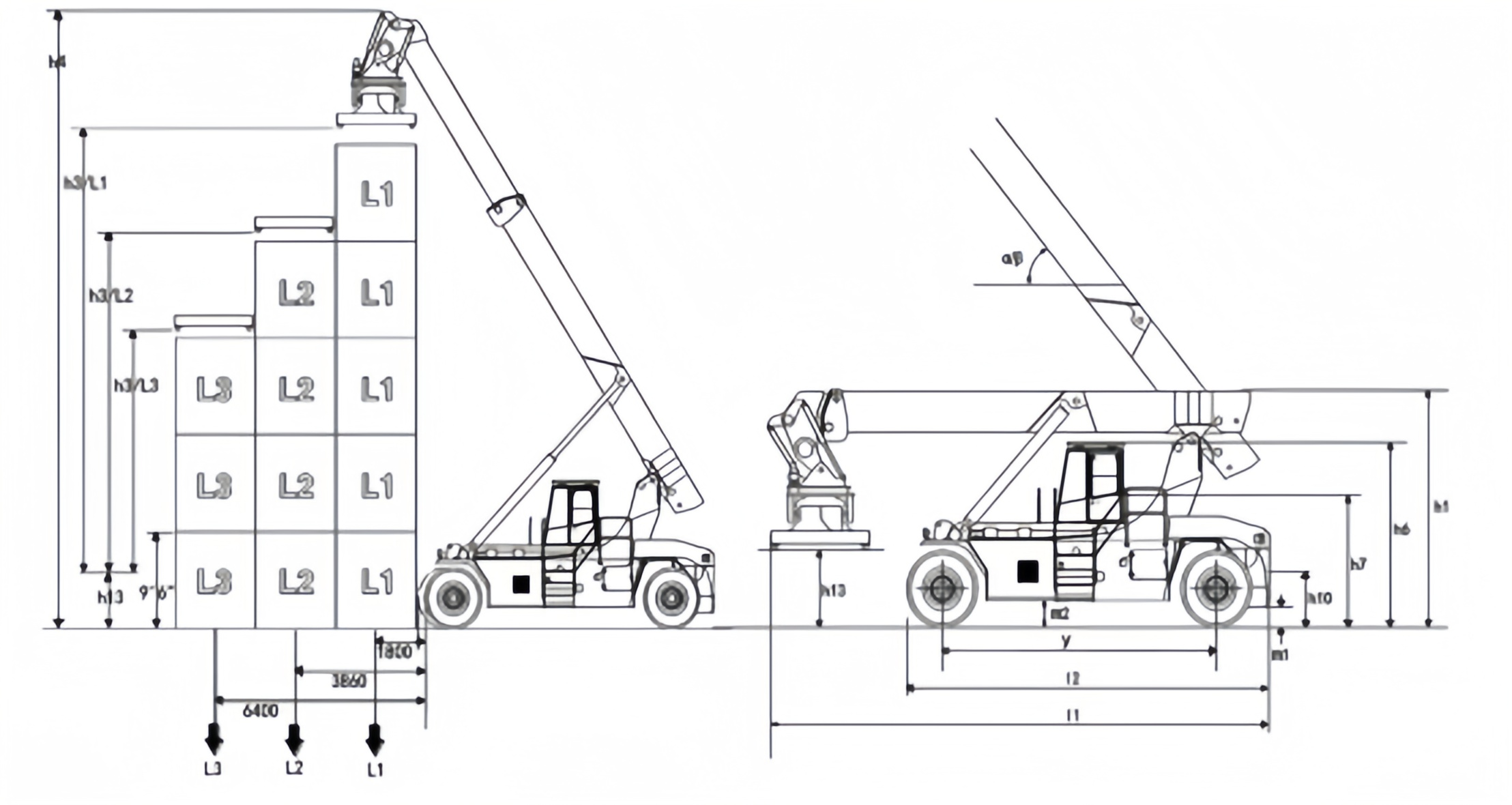

| Load capacity (L1,L2, L3) | Q(kg) | 45000/31000/16000 | |||||||

| Load centre, First row (L1) | c(mm) | 1800@6 floor, 2000@1-5 floor | |||||||

| Load centre, Second row (L2) | c(mm) | 3860 | |||||||

| Load centre, Third row (L3) | c(mm) | 6400 | |||||||

| Axle centre to spreader centre (L1-1/2 high) | x(mm) | 2800/2600 | |||||||

| Wheelbase | y(mm) | 6400 | |||||||

| Weights | Service weight | kg | 71600 | ||||||

| Axle load with load, front / rear (L1) | kg | 97900/14700 | |||||||

| Axle load without load, front / rear (L2) | kg | - | |||||||

| Axle load without load, front / rear (L1) | kg | 32400/35200 | |||||||

| Axle load without load, front / rear (L2) | kg | - | |||||||

| Wheel & Tyres | Tyre, front / rear. SE=(super-elastic), P= | P/P | |||||||

| Tyre size, front | 18.00*25/ 40pr | ||||||||

| Tyre size, rear | 18.00*25/ 40pr | ||||||||

| Wheels, number, front / rear (x=driven) | 4x/2 | ||||||||

| Track width, front | b10 | 3030 | |||||||

| Track width, rear | b11 | 2786 | |||||||

| Dimensions | Telescopic boom lift angle, Raised/ | /° | 61/0 | ||||||

| Height telescopic boom lowered | h1(mm) | 4760 | |||||||

| Lift (L1,L2,L3) | h3(mm) | 15300/14100/11350 | |||||||

| Height, telescopic boom extended | h4(mm) | 19000 | |||||||

| Height of overhead guard (cabin) | h6(mm) | 4000 | |||||||

| Height, operators seat / stand-on platform | h7(mm) | 2740 | |||||||

| Towing coupling height | h10 | 600 | |||||||

| Twist-lock height lowered | h13 | 1495 | |||||||

| Overall length with attachment | L1(mm) | 11618 | |||||||

| Overall length | L2(mm) | 8408 | |||||||

| Overall width | b1/b2 | 4180/3400 | |||||||

| Width of attachment 20'/40' | b3(mm) | 6050/12150 | |||||||

| Ground clearance minimum (two side) | m2(mm) | 330 | |||||||

| Ground clearance, centre of wheelbase | m1(mm) | 280 | |||||||

| Stacking aisle 20' container | Ast(mm) | 10225 | |||||||

| Stacking aisle 40' container | Ast(mm) | 13050 | |||||||

| Turning radius | Wa(mm) | 8550 | |||||||

| Minimum pivoting point distance | b13 | 3400 | |||||||

| Performance | Travel speed, with / without load | Km/h | 21/25 | ||||||

| Lift speed, with / without load | m/s | 0.28/0.39 | |||||||

| Lowering speed, with / without load | m/s | 0.39/0.39 | |||||||

| Tractive force,with / without load | KN | 370/- | |||||||

| Maximum tractive force, with / without load | KN | 408/- | |||||||

| Climbing ability, with / without load | % | 28/- | |||||||

| Maximum climbing ability, with / without | % | 32.5/34.5 | |||||||

| Acceleration time, with / without load | s | - | |||||||

| Service brake | Wet disc | ||||||||

| Battery voltage, rated capacity | V/Ah | 24V(2*12/150) | |||||||

| Drive | Engine manufacturer / type | Cummins QSM11 | |||||||

| Engine performance according to ISO 1585 | kw | 248 | |||||||

| Rated speed | 1/min | 2100 | |||||||

| Number of cylinders / displacement | /cm3 | 6/10820 | |||||||

| Fuel consumption according to VDI cycle | L/h | - | |||||||

| Other | Type of drive control | Torque conv.5/3 | |||||||

| Manufacturer / type | ZF 5WG261 | ||||||||

| TCU control mode | Self-action | ||||||||

| Drive axle model | Axle tech B110DS(Cummins Meritor) | ||||||||

| Steer axle model | W102 | ||||||||

| Spreader model | |||||||||

| Control system | Canbus | ||||||||

| Working pressure for attachments | bar | 140 | |||||||

| Oil flow for attachments | L/min | - | |||||||

| Noise level, at operator's ear, Overhead | dB(A) | 74 | |||||||

| Trailer coupling, design / type DIN | ?(mm) | 50 | |||||||

※ The technical information may vary by the update policy, the changes will be without prior notice.