INTRODUCTION

The Stationary Concrete pump is mainly use for Expressway, Road, Bridge, Light Rail and Private house construction scenarios.

FEATURES

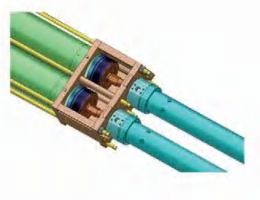

① HYDRAULIC SYSTEM

ONE-BUTTON TWIN PISTON RETURN

With one-button operation, both of the pistons can be automatically returned into the water tank, which effectively shortensthe time for replacing the piston and makes maintenance easier.

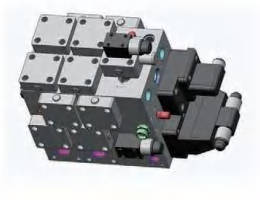

HYDRAULIC INTEGRATION BLOCK

It adopts hydraulic integrated valve group, compact design, Concise oil passage, Simple and reliable connection of hydraulic pipeline, Reduce the system fluid resistance keep the system in reasonable temperature.

ONE-BOTTON HIGH AND LOW PRESSURE SWITCHING

Switch between high and low pressure with one button, Easy pumping at high Floors.

② PUMPING SYSTEM

STRONG PUMPING SYSTEM

Advantages of high-pressurelarge-displacement conveying, unique design of mixing blades small mixing dead angles, strong design and strong suction performance, suitable for C15-C70 concrete pumping.

DUAL DRIVE LUBRICATION SYSTEM

Equipped with a dual-drive lubrication pump. which combines manual and fully-enclosed automatic re-lubrication technology, Effectively ensure the lubrication performance of moving parts and extends the service life.

COMMUTATION BUFFER TECHNOLOGY

Adopt the new generation of flexible control technology to minimize the hydraulic shock, Reduce noise and improve pumping stability

③ POWER SYSTEM

HIGH-END ENERGY SAVING TECHNOLOGY

Using the latest algorithm to optimize the engine power matching, The pumping efficiency increases by up to 15%, and the fuel consumption reduces by up to 10%.

ENGINE

Adopt famous international brand (DUETZ or COMMINS), big output power and torque not only guarantee the powerful working and complete combustion, also reduce the emissions.

④ ELECTRICAS SYSTEM

INTELLIGENT ELECTRIC CONTROL SYSTEM

A) EQUIPMENT MANAGEMENT

·DYNAMIC MONITORING Equipped with a powerful human-computer interaction system, Real-time feedback of equipment operating conditions.

·SAFE OPERATION Set multiple security protection modes to prevent misoperation and damage to equipment.

·SELF-DIAGNOSIS Real-time monitoring of equipment status, effectively improving troubleshooting time by 70%.

B) DATA ANALYSIS

·MAINTENANCE TIPS Prompt maintenance tips according to working hours and pumping volume.

C) INFORMATION MANAGEMENT

·DATA RECORDING Record running time of core componentssuch as pumps and engine.

·FUEL CONSUMPTION MANAGEMENT You can view daily and unit pumping fuel consumption.

EXCELLENT AUTOMATIC PROTECTION SYSTEM

D) OVERLOAD PROTECTION

When the engine is overloaded or over-speed, the system will automatically stop working to avoid damage to the engine and oil pump.

E) REAL-TIME MONITORING OF DIESEL

Automatic warning, when the fuel is insufficient, To ensure that the engine will not be damaged.

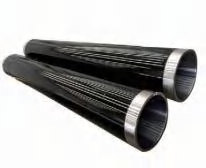

⑤ EXTREME WEAR-RESISTING TECHNOLOGY PROJECT CASE

DELIVERY CYLINDER

The inner layer is plated with chrome and its service life can reach to above 100,000m3 due to the good wear resistance.

GLASS PLATE/CUTTING RING

Made of rigid alloy with special process,extending service life.

SPECIFICATIONSS

Performance

| ITEMS | UNITS | SP100 .18.186D | |||||||||

| Max.Theo.Output(Low/ High) | m3/h | 100/55 | |||||||||

| Max. Concrete Pressure (Low/ High) | MPa | 9.7/ 18 | |||||||||

| Distribution Valve | / | S Valve | |||||||||

| Concrete Cylinder (Bore X Stroke) | mm | Diameter 200x1800 | |||||||||

| Hopper Size (CapacityxFeeding Height) | m3xmm | 600x1380 | |||||||||

| Max.Theo.Delivery Vertical Height | m | 320 | |||||||||

| Max.Theo.Delivery Horizontal Distance | m | 1100 | |||||||||

| Outlet Diameter | mm | DN 150 | |||||||||

Power system

| ITEMS | UNITS | SP100 .18.186D | |||||||||

| Engine | / | BF6M1013-25T3R | |||||||||

| Rated power | kW | 186 | |||||||||

| Rated Speed | r/min | 2300 | |||||||||

| Min.Speed | r/min | 800 | |||||||||

| Type of cooling | / | Water cooling | |||||||||

Hydraulic system

| ITEMS | UNITS | SP100 .18. 186D | |||||||||

| Hydraulic Pump | / | KAWASAKI | |||||||||

| Main Valve & Control Valve | / | Rexroth / EATON | |||||||||

| Type of circuit | / | Open | |||||||||

| Pumping Pressure | MPa | 32 | |||||||||

| Distribution Pressure | MPa | 19 | |||||||||

| Mixing Pressure | MPa | 10 | |||||||||

| Max.mixing Speed | r/min | 35 | |||||||||

| Hydraulic Oil Tank Capacity | L | 600 | |||||||||

| Fuel Tank Capacity | L | 200 | |||||||||

| Main Oil Pump Displacement | ml/r | 260 | |||||||||

| Type of cooling | / | Air cooling | |||||||||

Others

| ITEMS | UNITS | SP100 .18. 186D | |||||||||

| Dimensions(L×W×H) | mm | 7130X2065X2860 | |||||||||

| Total Weight | kg | 7360 | |||||||||

| Diameter of Delivery Pipe | mm | Φ125/Φ150 | |||||||||

| Max.Diameter of Aggregate | mm | Pebble 50, Crushed stone40 | |||||||||

| Reversal Mixing | / | Manual | |||||||||

| Supporting wheel & L-H Pressure Switch | / | Manual | |||||||||

| Lubrication System | / | Double pump, progressive oil separator | |||||||||

HIGHLIGHTS

★ High Configuration with International well-known brand components.

★ Tungsten steel glasses plate and cutting ring, which permits longer life.

★ Hydraulic legs facilitate pump positioning.

★ High and low pressure switching valve, you can adjust the working status of the pump at will just by pulling the handle.

★ The concrete piston can be returned to the cleaning tank, making it easier to repair and replace the piston.

Note: Actual unit may vary from the picture and specification as shown.