INTRODUCTION

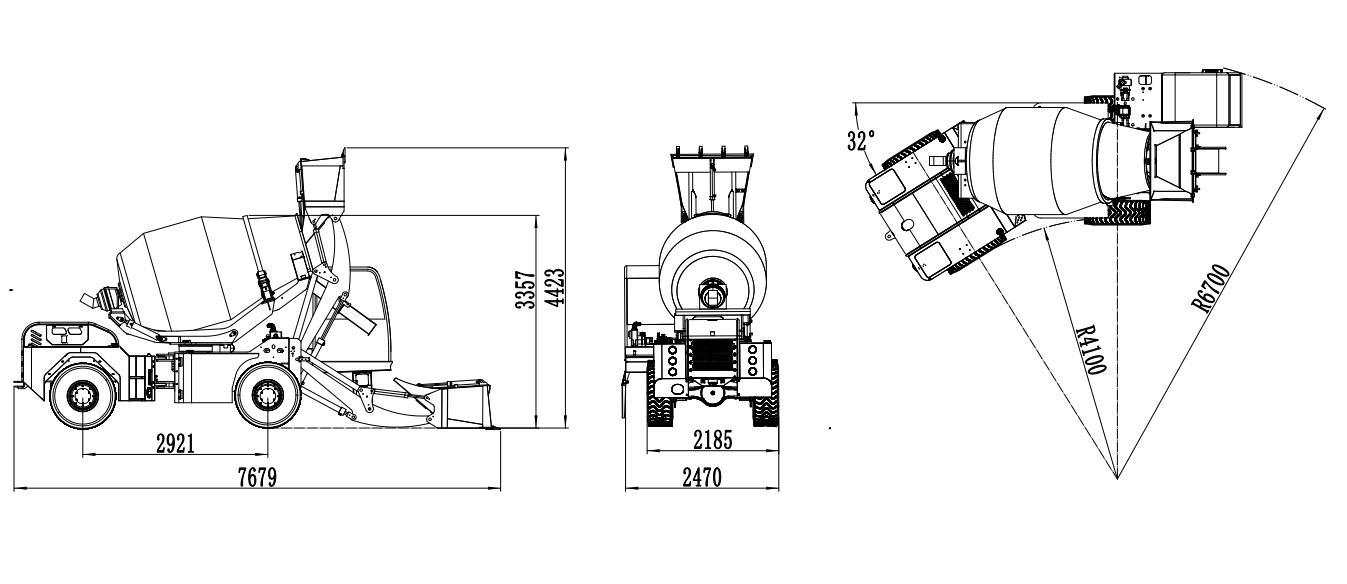

This product can replace generator sets, loaders, mixers and tankers. As well as more than six staff, is a new generation of building industry leading products. The tank can be rotated at 270 degrees with no dead ends on three sides.

FEATURES

1 Man-sized radiator Radiator adopts international advanced panel independent cooling system to ensure this the oil lifter quality and temperature control.

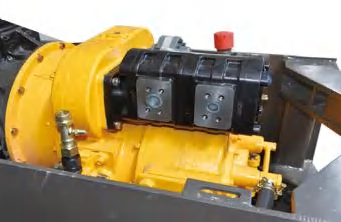

2 Duplex gear pump Duplex gear pump easy maintenance high pressure not easy to wear. It increases the oil inlet and outlet and ensures the required flow rate of the whole machine.

③ Oil-less bushing The machine uses oil-less bearing wear resistance is 100 times that of a common case because of butter only once a year.

④ Reduction gears of tanker It uses the BMS large torque motor which is from domestic famous manufacture a reasonable ratio maximizes efficiency.

⑤ Filter(Cleaner) It adopts self-sealing oil filter with high accuracy and convenient maintenance. Double pump lifter the oil in and out to effectively protect the life of hydraulic parts.

⑥ Tubing All tubing used international standard joint to make sure there is no oil leak large flow easy to maintenance and universal.

OVERALL

SPECIFICATIONS

Item | Specification | Unit | FT-3.5 |

Diesel Engine | Type | YCD4J22T-115 | |

Total displacement cylinders | 4330cc,4-in-line | ||

Injection | Direct injection and mechanical control | ||

Cooling system | Water-cooling,dry air filter | ||

Maximum power | Kw | 85 | |

Maximum torque | N-m/r/min | 390/1900 | |

Electric System | Generator | 28v-1260W 45A | |

Battery | 2*12V-60AH(272A) | ||

Speed | The first high speed/second high speed | Km/h | 0-17/0-33 |

The first low speed/second low speed | Km/h | 0-6/0-12 | |

Axle and Tyre | Rear axle oscillating | ± | 10° |

Tyre | 16/70-20 | ||

Mixing and Unloading | The geometrical volume of drum | L | 5500 |

The rotation speed of drum | r/min | 22 | |

Equipment Hydraulic System | Maximum flow rate | ml/r | 40/80 |

Maximum pressure | Map | 20 | |

Loading | Capacity | ? | 0.56 |

Times | 7 | ||

Maintenance and Oil filling | Fuel tank | L | 158 |

Total hydraulic system capacity | L | 158 | |

Engine | L | 14 | |

Weight | Operating weight | kg | 7550 |

Max Weight | kg | 16300 | |

Load-carrying capacity | kg | 8750 | |

Steering | Assisted by double displacement loading sensor power on steering wheel to turn, articulated steering. | ||

4*4 Four-Wheel Drive | Hydraulic torque converter gearbox, open hydraulic gear oil pump, and reverse gear control to control working speed and travelling speed. | ||

Brakes | External disc brake and emergency brake acting on four wheels, independent dual circuit brake and hand-control to braking. | ||

Water system | Hydraulic centrifugal self suction pump injection, the capacity is 14-16m3/h, Inside : it is 150L/min. The total capacity of two connected water tanks positioned opposite is 540L Visual flowmeter, the water intake of the roller by hand-control.

| ||

Cab | Closed cab with heating system,tilting front window, humanized seat flexible suspension and height adjustment are provided. | ||

※ The technical information may vary by the update policy, the changes will be without prior notice.