FEATURES

① HYDRAULIC SYSTEM

BOOM ANTI -VIBRATION TECHNOLOGY

Effectively reduce the vibration of the boom during pumping, the amplitude is reduced by 50 placing more accurate and extend parts life.

SWING CYLINDER AUTOMATIC PRESSURE RELIEF

It When shut down, the swing cylinders can release pressure automatically to ensure the safety of personnel.

CYLINDER LOCKING FUNCTION

Prevent the pistons from backsliding due to the gravity of concrete in the pipes when the pumping stops.

LARGE DIAMETER CARTRIDGE VALVE

Reduce the internal resistance of the hydraulic system and improve the working efficiency.

ONE-BUTTON TWIN PISTON RETURN

With one-button operation, both of the pistons can be automatically returned into the water tank, which effectively shortens the time for replacing the piston and makes maintenance easier.

ONE-BOTTON HIGH AND LOW PRESSURE SWITCHING

Switch between high and low pressure with one button, Easy pumping at high Floors.

② ELECTRIC SYSTEM

SELF-ADAPTIVE ENERGY SAVING TECHNOLOGY

Automatically match the engine's revolution with running status of pumping and boom moving perfectly, save more than 10uel.

SAFETY PROTECTION DEVICES

Equipped with vehicle tilt sensor, outrigger limit swith, rotary encoder, etc. More safe.

SELF DIAGNOSTIC MONITORING SYSTEM

The fault diagnosis system monitors the working condition of the engine and hydraulic system in real time. Sound and light alarm, more intelligent.

SWITCH LOGIC CONTROL OF DRIVING AND OPERATION

Can prevent the operator from misoperation.

③ POWER SYSTEM

EXTREME WEAR-RESISTANT TECHNOLOGY

DELIVERY PIPES

GLASS PLATE/CUTTING RING

High-strength alloy, special process, excellent durability.

HIGHLIGHT

★TP43RZ5 pump truck integrates high reliability, high economy, high safety and high durability. Chassis, power, electronic control. The hydraulic and pumping systems are reasonably matched, and have the advantages of strong adaptability to road conditions and construction sites, small blind areas for fabrication, large displacement, low maintenance costs and high cost performance.The main accessories are all selected from world-renowned brands, with excellent performance and reliable quality.

★The upper structure is newly designed, and the structural layout of the entire vehicle is better than that of peers and even first-class international brands. From the perspective of control, the distribution of the vehicle's center of gravity and optimal driving are fully considered.Control the viewing angle. The independent engine on the upper body is arranged in the same direction as the frame. The vehicle rides more stably, the control is more comfortable, the reversing viewing angle is wider, and the outlet connection pipe is installed butt-jointed.Faster and safer, the equipment quickly enters pumping working status after entering the site, greatly improving project efficiency.

★Industry-leading configuration of pumping system: This machine has the special advantage of high-pressure and large-displacement transportation. Users can adjust the height (or distance) and height of concrete transportation according to the project.Reasonable selection according to the displacement requirements. The industry's largest diameter 230mm concrete cylinder is used, which not only meets the needs of large displacement but also high-pressure push output.The design of the device has successfully solved the problem of slurry leakage in similar domestic pumps. It has greater superiority and reliability than other forms. The blade design is unique and the mixing is dead. It has a small angle and is designed to achieve industry-leading material suction performance, and can be adapted to the pumping of concrete formulas ranging from C15 to C70.

★Industry-leading configuration of pumping system: Equipped with a 170mm bore main cylinder that is larger than the industry's same-level vehicle-mounted pump, ensuring higher pumping outlet pressure and eliminating the need for construction to prevent losses and interruptions caused by pipe blockage, the end of the cylinder is equipped with a high-reliability structural limit mechanism. It also has a reverse pump function that can switch oil into the rod cavity.If a temporary blockage occurs, it can be used as a means to clear the blockage. Special configurations are added to the cylinder pipeline to achieve the lowest no-load pressure in the industry, reflecting excellent performance of equipment system.

★New technology + new process: the new double-ring structure technology of the carbide glasses plate and cutting ring, high tungsten carbide, has a lifespan that is twice as long as that of ordinary materials, and is superior to the maximum square volume of imported glasses plates can reach 50,000 square meters (C25).

★ Automatic throttle adjustment system: Using ECU and CPU closed-loop linkage control technology, the throttle is automatically adjusted according to equipment construction needs and load size to keep the engine running.The engine is always in the best working condition, the engine power is controlled in real time, and the power and operation are optimized in all working conditions. The fuel consumption is reduced by more than 10%, saving energy and effectively reducing cost.

★Stepless adjustment of pumping displacement: Introduce proportional control technology into concrete drag pumps, adjust through remote control or panel buttons, and change the mix by controlling the size of the current.The pumping volume of concrete can be infinitely adjusted within the range of 0-100m3 to adapt to different working conditions.

★Fully automatic one-button switching between high and low pressure: Just turn the electronic control button easily, and the switching between high and low pressure is completed in an instant. You can even switch between high and low pressure as needed during the pumping process. Flexible control experience, able to cope with various unfavorable factors and changes in concrete materials during the construction process.

★ Intelligent electronic control system: The application of professional integrated controllers in CAN bus communication mode makes the wiring lines simpler and more compact, and the protection level is higher to protect against faults. Lower rate and better seismic performance. Combined with the 7-inch large-screen human-machine interface, the operation is more flexible. The humanized and intelligent electronic control system integrates man and machine, easy to operate. It effectively prevents accidents caused by misoperation. Multiple automatic protection modes are set up in the control program to prevent misoperation from damaging the equipment, components, enhancing the reliability and safety of the system.

★Reversing buffer system: The reversing signal is monitored through the pressure switch. The controller gets the signal and immediately reduces the displacement of the main oil pump to a low level, so that the main oil cylinder can be reversed before reversing.The front speed has gradually decreased. After the reversal is implemented, the displacement of the CPU control system gradually rises back to the matching displacement value. The entire reversal process is smooth and without impact.

★Anti-backflow device: The whole vehicle is designed with a special anti-backflow device in the oil return line. During the maintenance and repair process of the equipment, there is no need to drain the hydraulic oil in the hydraulic tank oil, saving a lot of man-hours while effectively reducing secondary pollution sources and preventing environmental pollution from dripping during the oil draining process.

★ Concrete piston self-retracting system: With one-button operation, the double-rod concrete piston automatically retreats into the water tank, reducing the time to replace the concrete piston from more than 2 hours to 10 minutes, which avoids possible safety accidents caused by restarting the equipment during the replacement process. At the same time, the concrete piston can be checked before each pumping to find any problems.Problems can be dealt with in advance to avoid unexpected shutdowns during work. After each pumping, the concrete piston can be returned to the water tank for cleaning, grease maintenance, and extended maintenance and concrete piston life.

★Dual-drive lubrication system: Equipped with a dual-drive lubrication pump as standard, you can manually pump grease for lubrication before starting the machine and when cleaning and maintaining the equipment. During normal operation, the hydraulic drive is required throughout the process.Dynamic supply to each lubrication point, effectively ensuring the lubrication performance of moving parts. The fully enclosed automatic replenishing lubricating oil technology ensures the cleanliness of the lubrication system and prolongs the service life of each component.

★ Self-diagnosis monitoring system: Standard engineering professional-grade 7-inch large-screen human-machine interface to dynamically display operating parameters, additional fault diagnosis technology,and set multiple automatic dynamic protection and engine overspeed protection ensure reliable operation; the intelligent monitoring system monitors equipment working conditions in real time and displays mechanical, electrical, hydraulic, temperature and safety status. Display and inquiry, sound and light alarm, and fault self-diagnosis system.

Note: Actual unit may vary from the picture and specification as shown.

SPECIFICATIONS

Performance

| ITEMS | UNITS | TP43RZ5 | ||||||||

| Drive mode | Electronic drive | |||||||||

| Main cylinder inner diameter × stroke | mm | φ150 ×1800 | ||||||||

| Conveying cylinder inner diameter × stroke | mm | φ260 ×1800 | ||||||||

| Valve form | S valve | |||||||||

| Piston form | Split type | |||||||||

| Discharge opening size | mm | 1 75 | ||||||||

| Theoretical displacement of concrete | m 3 /h | Low pressure 150 | ||||||||

| m 3 /h | high pressure 85 | |||||||||

| Theoretical pumping pressure | MPa | Low pressure 5.9 | ||||||||

| MPa | High pressure 10.7 | |||||||||

| Theoretical pumping times | times / minute | Low pressure 26 | ||||||||

| High pressure 15 | ||||||||||

| Hopper volume | L | 7 00 | ||||||||

| Feeding height | m _ | ≤1.5 | ||||||||

| slump | cm _ | 10 ~ 23 | ||||||||

| Maximum aggregate size | mm _ | 40 | ||||||||

| System oil pressure | MPa | 32 | ||||||||

| High and low voltage switching | One-click automatic switching | |||||||||

Power system

| ITEMS | UNITS | TP43RZ5 | ||||||||

| Engine type | / | Four- stroke, in-line 6- cylinder | ||||||||

| engine model | / | MC 11.40-5 0 | ||||||||

| Engine power | kW/rpm | 297 | ||||||||

| Maximum torque | N.m/rpm | 1900/1000-1400 | ||||||||

| Exhaust emission standards | / | country V | ||||||||

| engine capacity | L | 10.518 | ||||||||

Gearbox

| ITEMS | UNITS | TP43RZ5 | ||||||||

| Model | / | HW19710T | ||||||||

| Control method | / | mechanical | ||||||||

| Number of forward gears | / | 10 gears | ||||||||

| Pumping gear | / | No. 10 gears | ||||||||

Water Pump

| ITEMS | UNITS | TP43RZ5 | ||||||||

| Drive mode | / | Hydraulic drive | ||||||||

| Control method | / | Manual | ||||||||

| Water pump model | / | 0720CS | ||||||||

| water pump maximum pressure | Mpa | 7 | ||||||||

| Concrete pipe cleaning methods | Washing / Dry cleaning | |||||||||

| Lubrication method | Grease manual lubrication Hydraulic oil automatic lubrication | |||||||||

Boom parts

| ITEMS | UNITS | TP43RZ5 | ||||||||

| Boom type | / | 5- section "RZ " folding | ||||||||

| The first section of the boom length/corner | mm/° | 8560/90 | ||||||||

| Second section arm length/corner | mm/° | 7626/180 | ||||||||

| Third section arm length/corner | mm/° | 7220/180 | ||||||||

| Fourth section arm length/corner | mm/° | 7600/240 | ||||||||

| Fifth section arm length/corner | mm/° | 7749/240 | ||||||||

| Turntable rotation angle | ° | ±360 | ||||||||

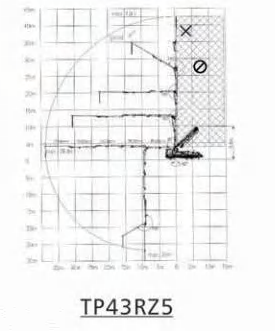

| Boom vertical height | m | 43 | ||||||||

| Boom horizontal length | m | 39 | ||||||||

| Conveying pipe diameter | DN 125 | |||||||||

| Fabric hose length | m | 3 | ||||||||

| Hydraulic system pressure | MPa | 32 | ||||||||

Branch leg

| ITEMS | UNITS | TP43RZ5 | ||||||||

| Maximum spread of front outriggers | mm | 8697 | ||||||||

| Maximum spread of rear outriggers | mm | 8946 | ||||||||

| Hydraulic system pressure | MPa | 20 | ||||||||

Power

| ITEMS | UNITS | TP43RZ5 | ||||||||

| transfer case | / | Zhu Te | ||||||||

| Main oil pump | / | Germany Rexroth | ||||||||

| Boom / outrigger oil pump | / | Germany Rexroth | ||||||||

| Auxiliary oil pump | / | Wanye | ||||||||

Others

| ITEMS | UNITS | TP43RZ5 | ||||||||

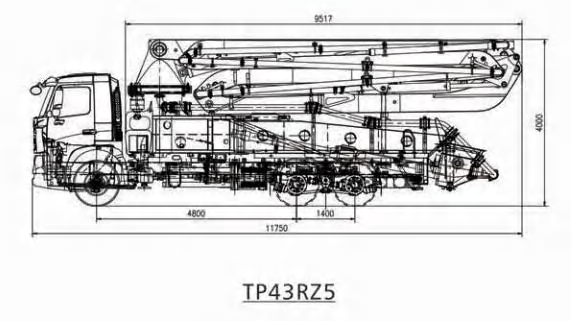

| Dimensions(L×W×H) | mm | 11725mm×2496mm×3996mm | ||||||||

| Total Weight | kg | 325,000 | ||||||||

| Chassis model | ZZ 5347 V 5 24HE1 | |||||||||

| Chassis drive mode | 6 ×4 | |||||||||

| maximum speed | km /h | 90 | ||||||||

| Wheelbase(first wheelbase/second wheelbase) | mm | 4800/1400 | ||||||||

| Wheelbase(front wheel/rear wheel) | mm | 2022/1830 | ||||||||

| tire size | / | 31 5/80R22.5 | ||||||||

| Minimum turning radius | m | 10.35 | ||||||||

| Control method | / | Manual / remote control | ||||||||

| remote control | / | Kaisang | ||||||||

| Water tank volume | L | 5 00 | ||||||||

| Fuel tank volume | L | 6 00 | ||||||||

| Hydraulic oil cooling method | / | air cooling | ||||||||