FEATURES

① HYDRAULIC SYSTEM

BOOM ANTI -VIBRATION TECHNOLOGY

Effectively reduce the vibration of the boom during pumping, the amplitude is reduced by 50 placing more accurate and extend parts life.

SWING CYLINDER AUTOMATIC PRESSURE RELIEF

It When shut down, the swing cylinders can release pressure automatically to ensure the safety of personnel.

CYLINDER LOCKING FUNCTION

Prevent the pistons from backsliding due to the gravity of concrete in the pipes when the pumping stops.

LARGE DIAMETER CARTRIDGE VALVE

Reduce the internal resistance of the hydraulic system and improve the working efficiency.

ONE-BUTTON TWIN PISTON RETURN

With one-button operation, both of the pistons can be automatically returned into the water tank, which effectively shortens the time for replacing the piston and makes maintenance easier.

ONE-BOTTON HIGH AND LOW PRESSURE SWITCHING

Switch between high and low pressure with one button, Easy pumping at high Floors.

② ELECTRIC SYSTEM

SELF-ADAPTIVE ENERGY SAVING TECHNOLOGY

Automatically match the engine's revolution with running status of pumping and boom moving perfectly, save more than 10uel.

SAFETY PROTECTION DEVICES

Equipped with vehicle tilt sensor, outrigger limit swith, rotary encoder, etc. More safe.

SELF DIAGNOSTIC MONITORING SYSTEM

The fault diagnosis system monitors the working condition of the engine and hydraulic system in real time. Sound and light alarm, more intelligent.

SWITCH LOGIC CONTROL OF DRIVING AND OPERATION

Can prevent the operator from misoperation.

③ POWER SYSTEM

EXTREME WEAR-RESISTANT TECHNOLOGY

DELIVERY PIPES

GLASS PLATE/CUTTING RING

High-strength alloy, special process, excellent durability.

HIGHLIGHTS

★ The boom is made of 700 -grade high-strength structural steel, which has high strength and light weight. It has been calculated through finite element and dynamic analysis. The optimized design of the structure , beautiful appearance of the arm and good load-bearing capacity.

★ The boom is R Z The five-section arm is flexible in folding and unfolding, and the maximum arm angle of 240°enables a wider range of fabrics to meet different needs. fabric demand.

★ The boom adopts a load-sensitive proportional control system, which enables the boom to run at high or slow speeds and has excellent operating performance. It can not only achieve infinite changes High-speed remote control can also realize emergency manual operation in emergency situations; the outriggers and boom control are interlocked to avoid misoperation and ensure the pump truck's operation construction safety.

★ The pumping system adopts electronically controlled commutation, which has stable performance and low failure rate.

★ The front outriggers adopt two-level X- shaped outriggers, and the rear outriggers adopt swing outriggers. The outriggers are flexible in expansion and contraction, have strong site adaptability, good stability, and can be used in difficult situations. different construction situations.

★ Using a Φ260 diameter, 1800 stroke concrete cylinder, it has good material suction, large pumping capacity, and high work efficiency, which can reach 150 times per hour. Cubic or more.

★ Prepare your own large-capacity water tank and high-pressure cleaning machine, so that you can easily clean the equipment after the work is completed.

★ Complete safety facilities, such as relief valves in the hydraulic system, balance valves on each boom cylinder, buffer valves and brakes in the slewing circuit,The hydraulic lock in the outrigger circuit and the interlock control in the electrical system ensure the safety of the equipment and better satisfy the operator. Comfort requirements.

★ The boom and pumping unit adopt long-distance wireless remote control operation, which not only improves the safety of the equipment, but also reduces the workload of the operator. degree, and can also be operated on the electronic control panel, which is convenient and flexible.

★ The electronic control system adopts professional engineering control. The system is simple and reliable. CAN bus output and special automotive grade wiring harness minimize the failure rate. It isalso equipped with a special display screen for the pump truck, which can display relevant working parameters and human-computer exchange, settings, fault warning and real-time query of parameters in real time Inquire .

★ The fully automatic centralized lubrication system and fully automatic fixed-point and timing matching lubrication technology can easily lubricate some main moving parts. Extends the service life of the equipment .

★ It has one-button anti-pump function; one-button high and low pressure switching function; one-button automatic double-cylinder piston simultaneous retraction function; one-button master cylinder inching function; The key swing cylinder inching function can easily meet the operating needs of various working conditions .

★ The design of the mixing device has successfully solved the problem of slurry leakage in similar domestic pumps, and has greater superiority and reliability than other types. The blades The design is unique, the mixing dead angle is small, the material suction performance is greatly improved, and it can be adapted to a variety of concrete formulas .

★ The maintainability is good, and the convenience and speed of system maintenance are fully taken into consideration when designing the structural layout.

★ Configure M A N The chassis of the technical engine has large power and torque, reliable performance, few failures and strong climbing ability. With high cost performance, road balance point between power, economy, emissions and cost, which can not only meet the extreme use requirements, but also make full use of fuel consumption. Reduce exhaust emission pollution.

★ The streamlined hopper, reasonable pumping installation inclination angle, and optimized cross-section "S" valve reduce the accumulation of material in the hopper and improve the pumping efficiency. Reduces pressure loss. Using unique stirring and S- valve size bushing sealing technology, the service life is effectively extended.

★ It can realize the function of supporting cloth on one side within a certain range, and the rotation angle is controlled electrically, ensuring the safety of construction and satisfying the needs of users. The construction needs of households in a narrow space or when site support is limited .

Note: Actual unit may vary from the picture and specification as shown.

SPECIFICATIONS

Performance

| ITEMS | UNITS | TP38RZ5 | ||||||||

| Drive mode | Electronic drive | |||||||||

| Main cylinder inner diameter × stroke | mm | φ150 ×1800 | ||||||||

| Conveying cylinder inner diameter × stroke | mm | φ260 ×1800 | ||||||||

| Valve form | S valve | |||||||||

| Piston form | Split type | |||||||||

| Discharge opening size | mm | 1 75 | ||||||||

| Theoretical displacement of concrete | m 3 /h | Low pressure 170 | ||||||||

| m 3 /h | high pressure 95 | |||||||||

| Theoretical pumping pressure | MPa | Low pressure 6.5 | ||||||||

| MPa | High pressure 11.6 | |||||||||

| Theoretical pumping times | times / minute | Low pressure 29 | ||||||||

| High pressure 16 | ||||||||||

| Hopper volume | L | 7 00 | ||||||||

| Feeding height | m _ | ≤1.5 | ||||||||

| slump | cm _ | 10 ~ 23 | ||||||||

| Maximum aggregate size | mm _ | 40 | ||||||||

| System oil pressure | MPa | 32 | ||||||||

| High and low voltage switching | One-click automatic switching | |||||||||

Power system

| ITEMS | UNITS | TP38RZ5 | ||||||||

| Engine type | / | Four- stroke, in-line 6- cylinder | ||||||||

| engine model | / | MC 11.40-5 0 | ||||||||

| Engine power | kW/rpm | 297/1600-1900 | ||||||||

| Maximum torque | N.m/rpm | 1900/1000-1400 | ||||||||

| Exhaust emission standards | / | country V | ||||||||

| engine capacity | L | 10.518 | ||||||||

Gearbox

| ITEMS | UNITS | TP38RZ5 | ||||||||

| Model | / | HW19710T | ||||||||

| Control method | / | mechanical | ||||||||

| Number of forward gears | / | 10 gears | ||||||||

| Pumping gear | / | No. 10 gears | ||||||||

Water Pump

| ITEMS | UNITS | TP38RZ5 | ||||||||

| Drive mode | / | Hydraulic drive | ||||||||

| Control method | / | Manual | ||||||||

| Water pump model | / | 0720CS | ||||||||

| water pump maximum pressure | Mpa | 7 | ||||||||

| Concrete pipe cleaning methods | Washing / Dry cleaning | |||||||||

| Lubrication method | Grease manual lubrication Hydraulic oil automatic lubrication | |||||||||

Boom parts

| ITEMS | UNITS | TP38RZ5 | ||||||||

| Boom type | / | 5- section "RZ " folding | ||||||||

| The first section of the boom length/corner | mm/° | 8130/90 | ||||||||

| Second section arm length/corner | mm/° | 6800/180 | ||||||||

| Third section arm length/corner | mm/° | 6350/180 | ||||||||

| Fourth section arm length/corner | mm/° | 6345/240 | ||||||||

| Fifth section arm length/corner | mm/° | 6300/220 | ||||||||

| Turntable rotation angle | ° | ±360 | ||||||||

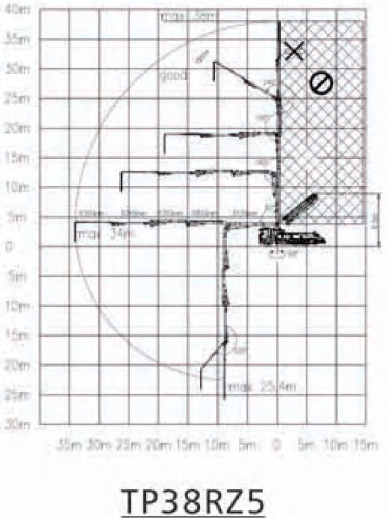

| Boom vertical height | m | 38 | ||||||||

| Boom horizontal length | m | 34 | ||||||||

| Conveying pipe diameter | DN 125 | |||||||||

| Fabric hose length | m | 3 | ||||||||

| Hydraulic system pressure | MPa | 35 | ||||||||

Branch leg

| ITEMS | UNITS | TP38RZ5 | ||||||||

| Maximum spread of front outriggers | mm | 6071 | ||||||||

| Maximum spread of rear outriggers | mm | 8151 | ||||||||

| Hydraulic system pressure | MPa | 25 | ||||||||

Power

| ITEMS | UNITS | TP38RZ5 | ||||||||

| transfer case | / | Zhu Te | ||||||||

| Main oil pump | / | Germany Rexroth | ||||||||

| Boom / outrigger oil pump | / | Germany Rexroth | ||||||||

| Auxiliary oil pump | / | Wanye | ||||||||

Others

| ITEMS | UNITS | TP38RZ5 | ||||||||

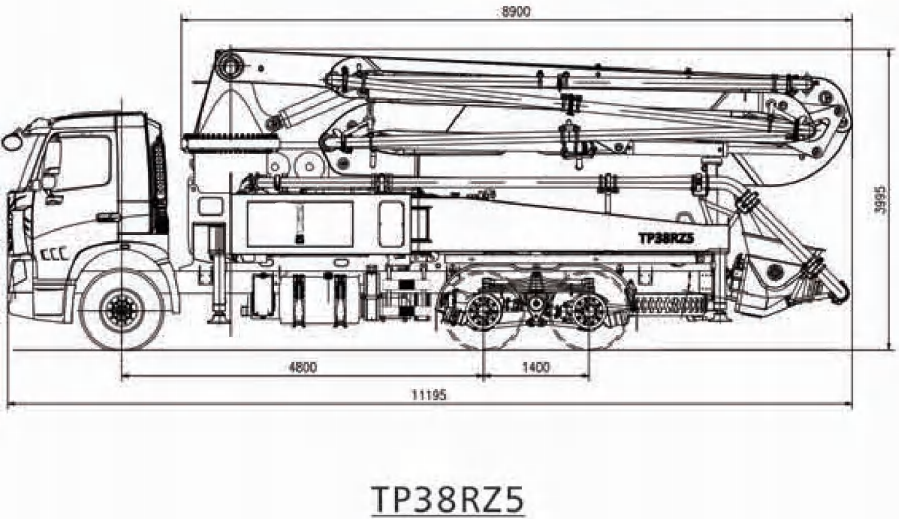

| Dimensions(L×W×H) | mm | 11195mm×2496mm×3995mm | ||||||||

| Total Weight | kg | 293,000 | ||||||||

| Chassis model | ZZ 5347 V 5 24HE1 | |||||||||

| Chassis drive mode | 6 ×4 | |||||||||

| maximum speed | km /h | 90 | ||||||||

| Wheelbase(first wheelbase/second wheelbase) | mm | 4800/1400 | ||||||||

| Wheelbase(front wheel/rear wheel) | mm | 2022/1830 | ||||||||

| tire size | / | 31 5/80R22.5 | ||||||||

| Minimum turning radius | m | 10.35 | ||||||||

| Control method | / | Manual / remote control | ||||||||

| remote control | / | German HBC | ||||||||

| Water tank volume | L | 6 00 | ||||||||

| Fuel tank volume | L | 6 00 | ||||||||

| Hydraulic oil cooling method | / | air cooling | ||||||||